Autonomous Fuelling System

The LNG fuelling system is fully autonomous. In this autonomous fuelling system, the driver positions the truck within a target area, then, by using RFID, the robotic system identifies the vehicle as a customer and starts the fuelling operation. The driver can supervise the fuelling process by means of live cameras and stop it remotely if needed.

Improved Durability

The LNG robotic system increases the life span of the LNG fuelling products.

The LNG robotic fuelling system is preventing the hose from touching the ground, reducing the wear on the hose. Additionally, the movements of the robotic system are programmed so that the mechanical stress is limited to a minimum.

When connecting and disconnecting, the LNG nozzle inside the tool of the LNG refuelling system is aligned perfectly with the receiver on the truck. This highly reduces the wear and tear on the parts in the front of the LNG nozzle.

Safety

LNG is natural gas which is cooled till -162°C. Spilling LNG while fuelling can cause serious skin burns. The main advantage of the LNG robotic fuelling system is that people can stay at a safe distance from the dispenser and fuel while the LNG is delivered to the vehicle.

The LNG gasses are highly flammable. The LNG fuelling system is ATEX certified to minimize the risk of an accident.

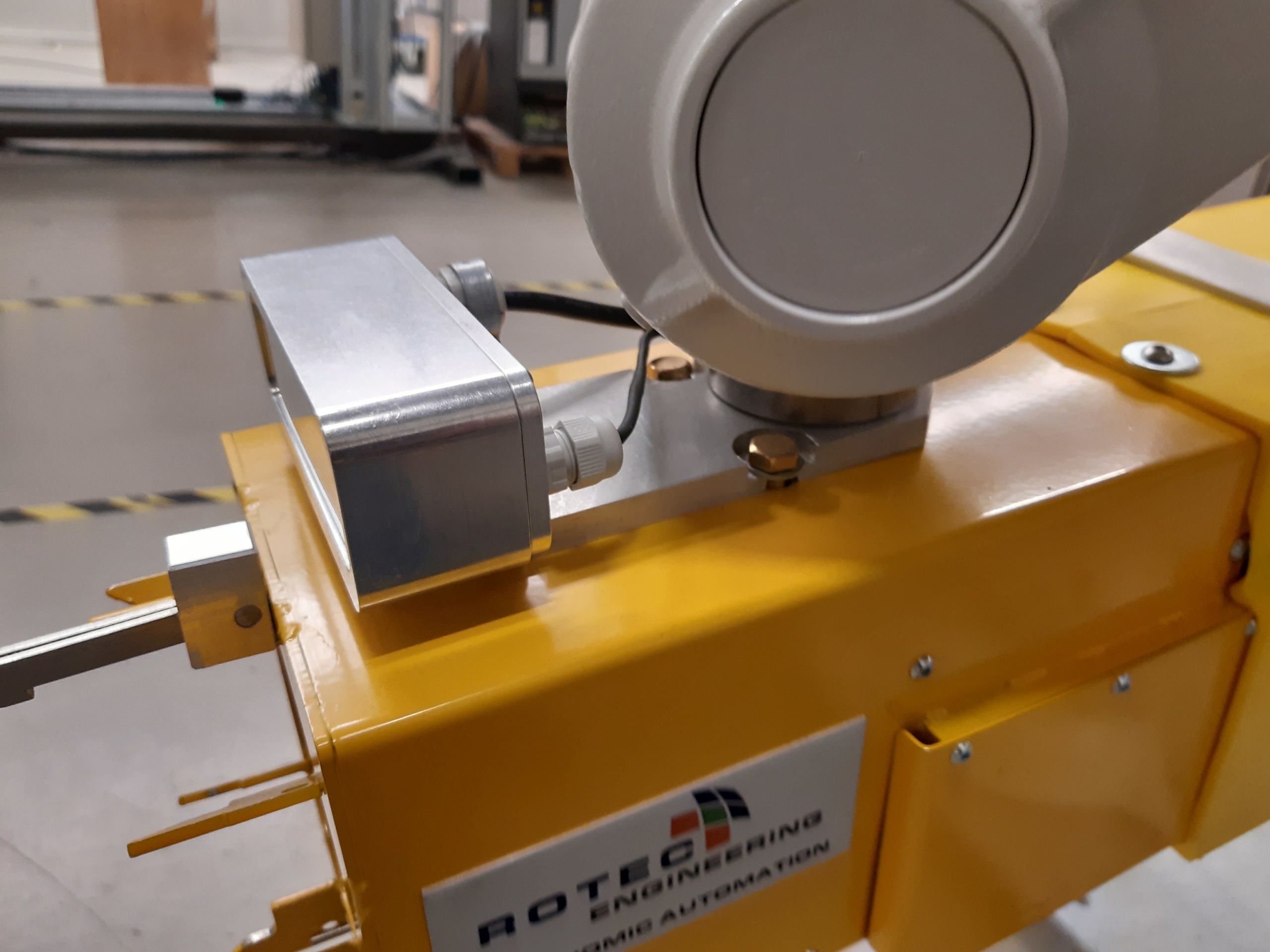

Robotic System

The LNG autonomous fuelling system consists of a 6 axes industrial robot with great freedom of movement. The robot is mounted in a compact and easy to transport slim frame that fits the existing fuelling islands, and that allows the system to perform fuelling operations on both sides of a gas station island. A vision system allows to recognize the receiver on the LNG tank of the truck. The robot arm is equipped with a tool designed by Rotec Engineering, provided with several safety systems capable of detecting and extracting leaked gases.

The system is equipped with safety means to protect users, children, and small animals against contact with the robot.